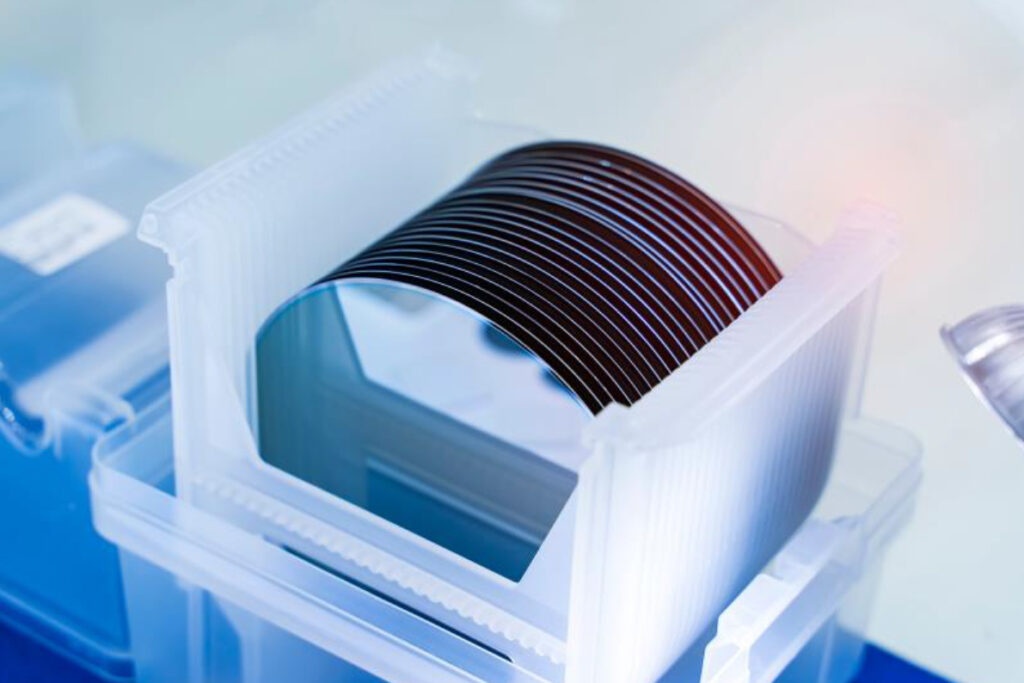

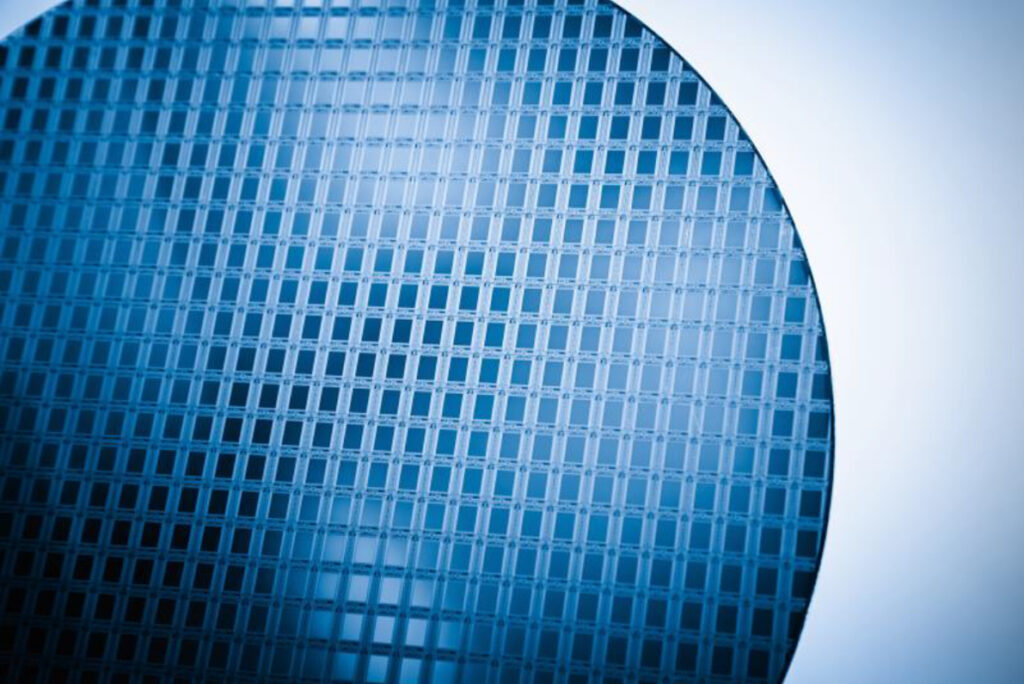

We offer you silicon wafers with almost any specification from leading international wafer manufacturers. Our high-purity wafers are grown using the Czochralski process (CZ) or the float zone process (FZ). With our highly specialized finishing options, we can meet your individual requirements. Small quantities can also be processed.

We will be happy to advise you on the right specifications for your application.

Please call us on +49-(0)8191-478747 or contact us by e-mail.